Blog

What is a Material Handling Integrator?

When it comes to optimizing your warehouse's efficiency and productivity, you may have heard the term "material handling integrator" or "systems integrator" thrown around. But what exactly does this mean, and how can it benefit your business? In this comprehensive guide, we'll dive into the world of material handling integrators and what you need to know.

What Is A Material Handling Systems Integrator?

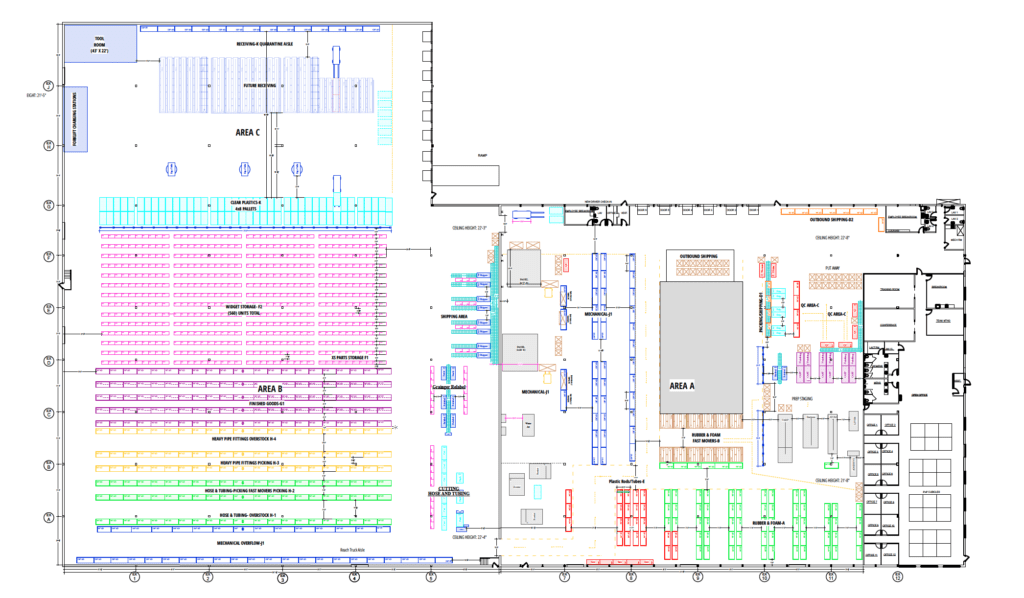

A material handling systems integrator is a professional who specializes in designing, engineering, integrating, and managing systems to improve the storage capacity and flow of materials in a warehouse or distribution center. They work with businesses to optimize their warehouse operations, from receiving and storing products to packing and shipping them out. Integrators serve as the main liaison throughout every stage of the project - from initial concept to final completion. A material handling systems integrator has a wide-ranging network of manufacturers enabling them to offer comprehensive solutions and adaptable lead times for all types of material handling needs, irrespective of the location.

Storage Coordinators collaborates with clients to create and execute an efficient material handling system. This involves offering design, engineering, permitting support, installation, and project management services to provide a comprehensive system that meets the deadline and budget. To reduce the installation risk of a project, Storage Coordinators provides their own professional in-house non-union or union laborers and installers - unlike others who sub out their labor.

Why Hire A Material Handling Integrator?

Hiring a material handling integrator/systems integrator can offer several benefits for your business, including:

- Increased productivity and efficiency: Integrators can design systems that streamline processes, reduce labor costs, and optimize space utilization, ultimately improving overall productivity and efficiency.

- Enhanced safety: Integrators are trained to design and engineer systems that prioritize safety, reducing the risk of accidents or injuries in the workplace.

- Customized solutions: Integrators can create tailored solutions to meet your business's unique needs, from designing a new warehouse layout to implementing automated systems.

The Process of Working with a Material Handling Integrator

Working with a material handling integrator typically involves several stages including:

- Consultation: The integrator will meet with you to discuss your business's current processes, challenges, and goals.

- Design: The integrator will create a customized design plan, including layout, equipment, and system specifications.

- Implementation: The integrator will oversee the installation and implementation of the new system, working with your team to ensure a seamless transition.

- Optimization: The integrator will continue to work with your team to monitor and optimize the new system, making any necessary adjustments to maximize efficiency and productivity.

Conclusion

In today's fast-paced business environment, optimizing your warehouse's efficiency and productivity is critical for success. Working with a material handling integrator can offer a range of benefits for your business, from increased productivity to enhanced safety and customized solutions. Consider reaching out to us at Storage Coordinators to see how we can help take your warehouse operations to the next level. Call us today at (610) 328-7666

Contact US

FILL OUT THE FORM BELOW AND OUR STORAGE EXPERTS WILL GET BACK TO YOU WITHIN 1 BUSINESS DAY.