12 Reasons to Work With A Warehouse Design Consultant

It's critical to work with an experienced team who will take the time to thoroughly understand your needs. Here are some top reasons why hiring a warehouse design consultant could be beneficial to your business:

-

Increase Productivity: Our team can help you design a layout that maximizes workflow efficiency and productivity, reducing the time it takes to move inventory and complete orders. We can also design a layout that streamlines your order fulfillment process, reducing the time it takes to fulfill orders, reducing errors, and improving customer satisfaction.

- Reduce Labor Costs: By optimizing your workflow, we can also help you reduce labor costs by streamlining your operations and eliminating inefficiencies.

-

Increase Storage Capacity: We can help you design a layout that maximizes your storage capacity, allowing you to store more inventory in your existing warehouse space.

-

Determine Your Warehouse Space Needs: We help clients determine their required warehouse space before beginning property searches, saving clients time and money.

-

Unbiased Storage Rack and Forklift Opinions: We collaborate with various manufacturers to provide unbiased recommendations for storage rack systems and forklift options. This ensures you get the best solutions for your needs.

-

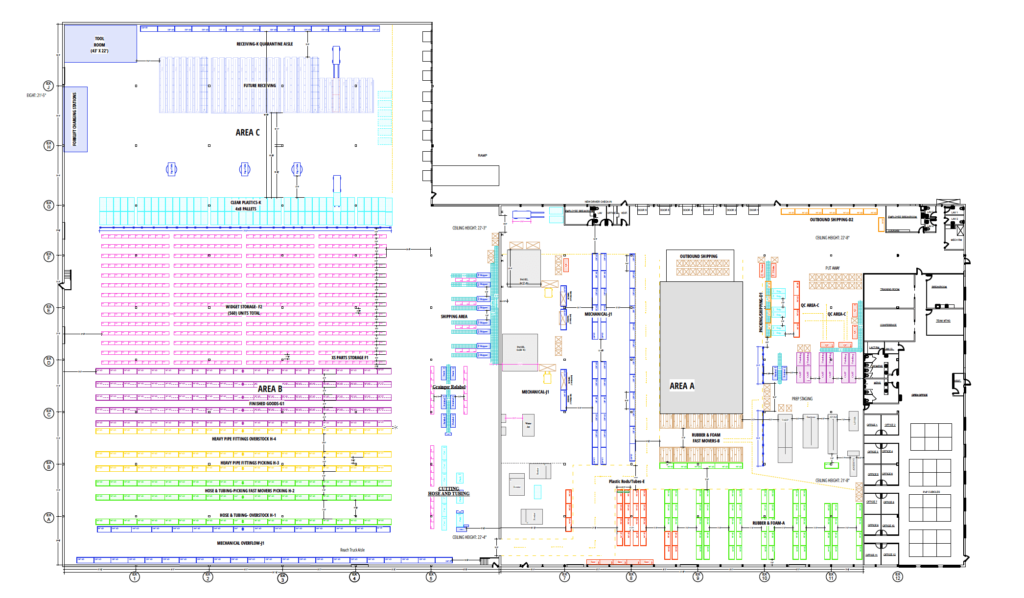

Detailed CAD Drawings: Our team offers detailed computer-aided design (CAD) drawings with multiple warehouse layouts and design options.

-

High-Density Storage Rack Options: We offer high-density storage rack options that can reduce your square footage requirements and save you significant money on real estate costs.

-

Extensive Inventory: We conveniently stock both new and used pallet rack products at our warehouses in the United States.

-

Future-Proof Your Warehouse: We can help you design a warehouse that can adapt to changes in your business and industry, ensuring your warehouse remains efficient and relevant for years to come.

-

Building Code and Safety Standards: Our team has a thorough understanding of typical building code requirements and warehouse safety standards, ensuring your warehouse is up to code and safe for your workers.

-

Racking Style Determination: Our team is experienced in Selective, Structural, Pushback (LIFO), Pallet Flow (FIFO), Drive-In, Carton Flow, and other rack styles. We can help you determine which style is best for your specific operations.

- Maximize Budget: We offer a range of cost-saving solutions, such as integrating pre-owned materials or re-configuring existing material whenever possible. Additionally, we take the time to survey your existing materials to find ways to maximize their potential and reduce waste. By doing so, we help you optimize your warehouse operations while keeping your budget in mind. We have even purchased client's existing material and provided credit towards purchase of new material.

Storage Coordinators can handle the warehouse consultation or provide complete turnkey services (design consultation, engineering, material, installation, project management) tailored to our clients’ specifications and we act as the point of contact from conception to completion of every project.

Our Process

Here is our general step-by-step process for a turnkey project (though this is tailored to each company’s individual needs and is just to provide an overview)

- Understanding the Need/Initial Meeting: We meet with the client to understand their goals and objectives for the project. The initial meetings may be performed remotely or in-person at a site visit.

- Orientation/Interviews/Site Visit: We interview various warehouse personnel, facility managers, executive management to understand business functions, historical distribution, transportation, future growth plans, etc. We may also need to come out to perform a site survey if the client does not have existing CAD drawings.

- Data Collection: Storage Coordinators will need certain data and information to be furnished by the client in order to design the optimal facility. Though each project is unique we will generally request the following data:

- Company sales growth projections including line of business and planned product modification or development

- Product information such as a list of SKU’s and quantities, future projected SKU quantities, dimensions of individual SKU items and pallets

- Product volume information such as frequency and historical replenishment of stocked pallet inventory, individual SKU’s, outbound SKU turnover rates, and SKU volume of fast movers at maximum output

- Receiving profiles including trucks received per day, shipments received per day, receiving turnaround time, and received items processing

- Facility operations including work and product flow, maximum capacity work and product flow, employee positions and responsibilities, employee hours and shifts, and existing requirements for workstations or office spaces

- Shipping profiles including average size of outgoing shipments, frequency of outgoing shipments, pieces, and cartons per day by week, and outgoing items processing

- Logistics such as typical shipping methods and number of existing docks/loading bays

- Existing structure including a .dwg file of the facility, current racking or shelving quantities and sizes, structural items or utilities that impede the space and should not be modified, and computer drafted drawings for any planned changes to the existing structure

- Project budget information (if available)

- Data Analysis: After collecting all the necessary data, our team of experts will analyze the information to gain insights into your facility's current operations. This analysis will enable us to create the most efficient layout options that will maximize your storage capacity, improve your productivity, and reduce your operational costs.

- Layout Development & Review: After analyzing the necessary data, we develop several layout options and present them to the customer. As part of the scope, we work to create an optimal flow of incoming (raw goods) and outgoing (finished goods) items, which ensures that all materials move efficiently through the warehouse. This involves strategically placing storage solutions such as pallet rack, shelving, push back rack, carton flow, and other material handling products in order to create an organized and streamlined layout. By optimizing the flow of goods, we can reduce inefficiencies such as wasted time and labor, minimize the risk of damage to products, and maximize the use of available space. Our goal is to help our clients achieve a warehouse layout that meets their specific needs and contributes to the overall success of their business. There is a phased approach to the design:

- In Phase 1, we provide up to 3 layout options based on the preliminary warehouse drawing, which may include pallet rack, shelving, push back rack, carton flow, and other material handling products as needed.

- In Phase 2, we submit a preliminary warehouse drawing version 2 for review, which also includes various material handling products as needed.

- In Phase 3, we collect all the pertinent information on what the customer likes and does not like about the version 2 drawing and apply it to the final warehouse drawing set. This includes a plan view drawing and elevation view drawings.

- Bill of Material and Bid Requests: After finalizing the layout, we develop a bill of material and request bids from our suppliers for the various systems involved.

- Bid Gathering and Quote Presentation: We gather bids and formalize a quote to send to the client. We present the quote to the customer, along with the layout, to ensure that they fully understand the proposal.

- Contract Award: After the material handling contract is awarded, we order and pack the materials and then schedule installation. We coordinate the installation with suppliers, our own expert installers, and the customer.

- Installation and Walkthrough: To finish off the project, we source our own in-house installation crew that can handle both union and non-union projects. Our competitors will try to sub this part out, but we take pride in our own expert team. Once installation is complete, we do a walkthrough with the customer to ensure that everything has been done to their satisfaction.

We take pride in our thorough and collaborative approach to our consultations, which allows us to deliver turnkey solutions that meet each company’s unique needs. Call the experts at Storage Coordinators today at (610) 328-7666.

Storage Coordinators has become a recognized leader in warehouse design consultation. We have over 30 years of experience in storage space, product flow consultation, and design. We have built our reputation by providing clients with what they need to increase productivity and their bottom line – on top of maximizing space and storage capacity. Consulting clients range from Fortune 500 companies down to small businesses.

Services

- Warehouse Design & Layout (New Construction, Relocation, Remodel)

- Project Management, Systems Integration and Implementation

- Material Handling/Storage Equipment Specification and Selection

- Shelves adjustable at 1 1/2″ increments.